EQUIPMENT

X-Ray Equipment

Aegleteq, sell, supply, install and maintain, a wide range of industrial x-ray equipment.

“high output stability, robust construction and a choice of focal spots to meet all requirements ”

“SMART EVO Controllers Where portability and functionality is required”

“‘XMB transportable. Small, powerful and reliable’.”

The wide range of uses

calls for a universal, easy to use control system realised in the YXLON MGi or COMET iVario. The set-up modes are menu driven. All signals, operating mode and fault diagnosis of internal or external errors are displayed in clear text which can be easily displayed in a number of optional languages. Additional error indications are given by numerical codes. Furthermore, 100 programs can be stored for future use, and when connected through the serial port interface, an infinite number of programs may be stored on the host computer, if required. utilisation of the inspected item within the production process.

Industrial equipment ranges

from 100 kV up to 600 kV. The typical application of each system is tailored towards specific target areas like low density applications, biological specimens (pathology), plastics and rubber compounds (100kV) and aluminium and steel applications like casting inspection (160 kV and 225 kV). Iron castings, steel parts etc with greater densities are taken care of by the 320kV to 600 kV range of equipment. These unipolar/bipolar 40kHz X-ray ‘stationary type equipment feature a very high output stability, a precise energy setting and an extremely fast change over to any selected new value. Any fluctuation or deviation of set values is controlled and corrected within microseconds. In addition these features reduce inspection times considerably and highly qualify the system for in line inspection in fast, completely automated production lines

Where portability is required

The SMART EVO Constant Potential equipment are comprised of the best components and assembled with the utmost care – making them reliable, long lasting and a sound investment. They are fitted with a high quality metal ceramic X-ray tubes and the robust composite casing now protects all vital parts even better. The systems meet the IP65 standard, making them fully operational in dusty and wet conditions. The range of light-weight and easy to handle directional and panoramic from 160 kV up to 300 kV meet all the discerning Contractor needs with ergonomic design for easier use. Starting weights for these fast ramping full power units range from 22 to 29 kg make the SMART EVO 300DS easy to handle and re-position. A broad temperature range from -20°C to +50°C makes the EVO systems reliable and ensures smooth operation even in extreme environments. The intuitive interface allows for a smarter workflow with the designed from scratch all new controller.

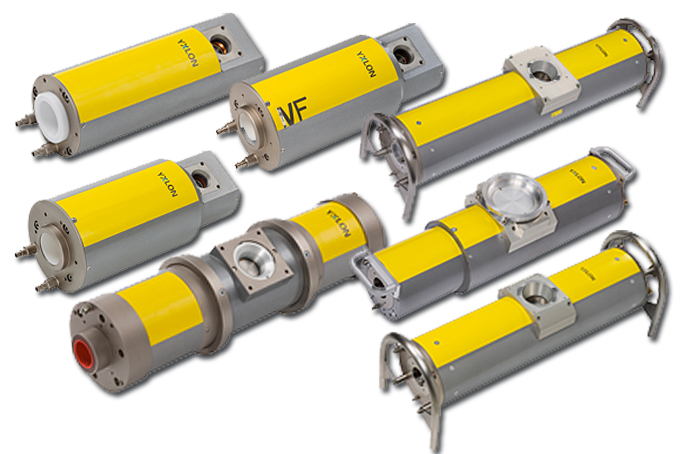

Where a smaller tubehead is required.

The Y.XMB transportable equipment is available as a 100 kV, 160 kV and 225 kV with X-ray power up to 2.25 kW at high frequency for stable, powerful exposures. All Y.XMB can be fitted with panoramic, directional and fan beam X-ray tubes. These are all available with different size focal spots.

Where portability is required

The SMART EVO Constant Potential equipment are comprised of the best components and assembled with the utmost care – making them reliable, long lasting and a sound investment. They are fitted with a high quality metal ceramic X-ray tubes and the robust composite casing now protects all vital parts even better. The systems meet the IP65 standard, making them fully operational in dusty and wet conditions. The range of light-weight and easy to handle directional and panoramic from 160 kV up to 300 kV meet all the discerning Contractor needs with ergonomic design for easier use. Starting weights for these fast ramping full power units range from 22 to 29 kg make the SMART EVO 300DS easy to handle and re-position. A broad temperature range from -20°C to +50°C makes the EVO systems reliable and ensures smooth operation even in extreme environments. The intuitive interface allows for a smarter workflow with the designed from scratch all new controller.

Where a smaller tubehead is required.

The Y.XMB transportable equipment is available as a 100 kV, 160 kV and 225 kV with X-ray power up to 2.25 kW at high frequency for stable, powerful exposures. All Y.XMB can be fitted with panoramic, directional and fan beam X-ray tubes. These are all available with different size focal spots.

“high output stability, robust construction and a choice of focal spots to meet all requirements ”

The wide range of uses

calls for a universal, easy to use control system realised in the YXLON MGi or COMET iVario. The set-up modes are menu driven. All signals, operating mode and fault diagnosis of internal or external errors are displayed in clear text which can be easily displayed in a number of optional languages. Additional error indications are given by numerical codes. Furthermore, 100 programs can be stored for future use, and when connected through the serial port interface, an infinite number of programs may be stored on the host computer, if required. utilisation of the inspected item within the production process.

“SMART EVO Controllers Where portability and functionality is required”

Industrial equipment ranges

from 100 kV up to 600 kV. The typical application of each system is tailored towards specific target areas like low density applications, biological specimens (pathology), plastics and rubber compounds (100kV) and aluminium and steel applications like casting inspection (160 kV and 225 kV). Iron castings, steel parts etc with greater densities are taken care of by the 320kV to 600 kV range of equipment. These unipolar/bipolar 40kHz X-ray ‘stationary type equipment feature a very high output stability, a precise energy setting and an extremely fast change over to any selected new value. Any fluctuation or deviation of set values is controlled and corrected within microseconds. In addition these features reduce inspection times considerably and highly qualify the system for in line inspection in fast, completely automated production lines

“‘XMB transportable. Small, powerful and reliable’.”

Download

Download product brochures